Coffee Roasting: Gerhard A. Jansen --- and other Books on Roasting

One of the books about roasting that many roasters are hunting for is "Coffee Roasting -- Magic, Art, Science, Physical changes and chemical reactions" by Gerhard A. Jansen who was heading the R-n-D of Probat for a number of years at the conclusion of a long career at the company. Probat-Werke in Emmerich published the booklet in 2006.

Jan van der Weel owns a copy and he kindly let me have it for a few days. The seventy-one pages of the book are crammed with information so it takes more than one reading to grasp enough and to understand it all one would need a degree in food chemistry.

A coffee bean has a million cells, I learned. During the roasting process, the rising bean temperature also heats up the water inside the bean. At normal atmospheric pressure, this water would boil at 100ºC but inside the bean, the cells more or less keep the water closed in and the cell gets in a state like a pressure cooker: the increasing pressure from the steam prevents boiling and pressure builds up further. At around 150ºC the beans that were hard like glass in their green, room temperature state, transform into a rubber-like condition. Cell walls become thinner, cells grow in size and steam and a gas mixture (carbon dioxide, carbon monoxide and others) escapes through week spots in the bean. A cracking sound can be heard.

In the many examples that Jansen discusses, the roasting time is 10 minutes maximum and the temperature is always rising, the beans keep growing darker until the end of the roast. Except for some super fast test roasts, temperatures in his examples have a steady rate of rise (unlike the roast profiles I aim for these days).

One of the details that Jansen explains peaked my interest.

In his illustration, one can see how furfural is composed gradually from the beginning of the roast, with a max production for a while after first crack sets in but the sweetness deteriorates fast as the temperature keeps rising and the beans grow darker than a light "filter" roast.

I am wondering if this pleasant caramel-like taste could be kept from decomposing during an extended roast after First Crack with very little Rate of Rise in the bean temperature. It could maybe keep this compound and other 'sweet' compounds intact, or allow more of these to be composed, while the acidity of other compounds is diminishing.

Jansen does not discuss this option, but what he does write keeps my hopes up.

In his conclusion, Jansen states that there is still much that we don't know about coffee.

I loaded 250g of Burundi beans (moisture 10.1% as measured by the Wile instrument for coffee) and I passed to Artisan these targets for my PID to manage on the roaster:

070.0ºC at 1 minute

109.0ºC at 2 minutes

142.0ºC at 3 minutes

166.0ºC at 4 minutes

184.0ºC at 5 minutes

197.0ºC at 6 minutes

206.0ºC at 7 minutes

210.5ºC at 8 minutes

215.0ºC at 9.25 minutes

The last stretch is longer than the others because I had noticed that the PID knows better how to cruise along tight margins when I don't interfere with temp points around First Crack, since that's mostly a little turbulent part of the roast anyway and while it is managing a balance there, I'd best not be shouting commands at it. In the graph below, you can see how the First Crack (between 7:00 and 7:30) does cause some waves but the Bean Temperature remains largely on coarse.

The beans smell very nice and the roast color is relatively light while still excellent for espresso. I wish I had someone near who is good at cupping tomorrow, but I will have to let the beans rest for a week, then grind on the Compak R120, brew on the Londinium L1-P and taste the espresso!

Thanks again to Jan van der Weel for letting me read this very rare and much sought after book.

PS 5 June 2018 on Instagram:

|

| A typical coffee bean has a million cells |

A coffee bean has a million cells, I learned. During the roasting process, the rising bean temperature also heats up the water inside the bean. At normal atmospheric pressure, this water would boil at 100ºC but inside the bean, the cells more or less keep the water closed in and the cell gets in a state like a pressure cooker: the increasing pressure from the steam prevents boiling and pressure builds up further. At around 150ºC the beans that were hard like glass in their green, room temperature state, transform into a rubber-like condition. Cell walls become thinner, cells grow in size and steam and a gas mixture (carbon dioxide, carbon monoxide and others) escapes through week spots in the bean. A cracking sound can be heard.

In the many examples that Jansen discusses, the roasting time is 10 minutes maximum and the temperature is always rising, the beans keep growing darker until the end of the roast. Except for some super fast test roasts, temperatures in his examples have a steady rate of rise (unlike the roast profiles I aim for these days).

One of the details that Jansen explains peaked my interest.

"Some volatile compounds increase in quantity with an increased roasting degree, others in turn increase to a certain roasting degree and subsequently begin to decompose when the roasting degree begins to rise. Over and above this, there are volatile aromatic compounds that after a tendency to increase and decompose, are recomposed in the continued course of roasting." (page 55)One such volatile compound, Jansen explains, is Furfural (C5H4O2), a compound of furans which produce a pleasant taste which is caramel-like to woody.

"The maximum furfural concentration is already reached at a very light roasting degree. The continuance of roasting, after a value held more or less constant, brings about a gradual decomposition of this substance."

In his illustration, one can see how furfural is composed gradually from the beginning of the roast, with a max production for a while after first crack sets in but the sweetness deteriorates fast as the temperature keeps rising and the beans grow darker than a light "filter" roast.

I am wondering if this pleasant caramel-like taste could be kept from decomposing during an extended roast after First Crack with very little Rate of Rise in the bean temperature. It could maybe keep this compound and other 'sweet' compounds intact, or allow more of these to be composed, while the acidity of other compounds is diminishing.

Jansen does not discuss this option, but what he does write keeps my hopes up.

In his conclusion, Jansen states that there is still much that we don't know about coffee.

"There are evidently still unidentified aromatic substances in the coffee bean which, although present in hardly measurable concentrations, still have a very effective say in determining the coffee aroma."Inspired by this exposé, I again tried out the idea of a declining Rate of Rise, as advised by Scott Rao, and a somewhat longer development time with a very small ever declining RoR, much like the Natural Roast discussed by Marko Luther of the Artisan software.

I loaded 250g of Burundi beans (moisture 10.1% as measured by the Wile instrument for coffee) and I passed to Artisan these targets for my PID to manage on the roaster:

070.0ºC at 1 minute

109.0ºC at 2 minutes

142.0ºC at 3 minutes

166.0ºC at 4 minutes

184.0ºC at 5 minutes

197.0ºC at 6 minutes

206.0ºC at 7 minutes

210.5ºC at 8 minutes

215.0ºC at 9.25 minutes

The last stretch is longer than the others because I had noticed that the PID knows better how to cruise along tight margins when I don't interfere with temp points around First Crack, since that's mostly a little turbulent part of the roast anyway and while it is managing a balance there, I'd best not be shouting commands at it. In the graph below, you can see how the First Crack (between 7:00 and 7:30) does cause some waves but the Bean Temperature remains largely on coarse.

The beans smell very nice and the roast color is relatively light while still excellent for espresso. I wish I had someone near who is good at cupping tomorrow, but I will have to let the beans rest for a week, then grind on the Compak R120, brew on the Londinium L1-P and taste the espresso!

Thanks again to Jan van der Weel for letting me read this very rare and much sought after book.

PS 5 June 2018 on Instagram:

|

| I started the PID program a few seconds after starting Artisan, hence a delay |

Some other books on coffee roasting:

|

| Handbuch Kaffeerösten zu Hause -- Claus Fricke |

|

| Modulating Coffee -- Rob Hoos |

|

| Home Coffee Roasting -- Kenneth Davids |

|

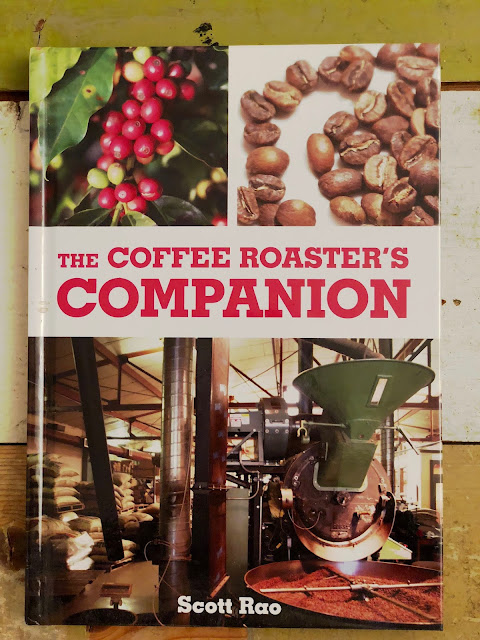

| The Coffee Roaster's Companion -- Scott Rao |

Reacties