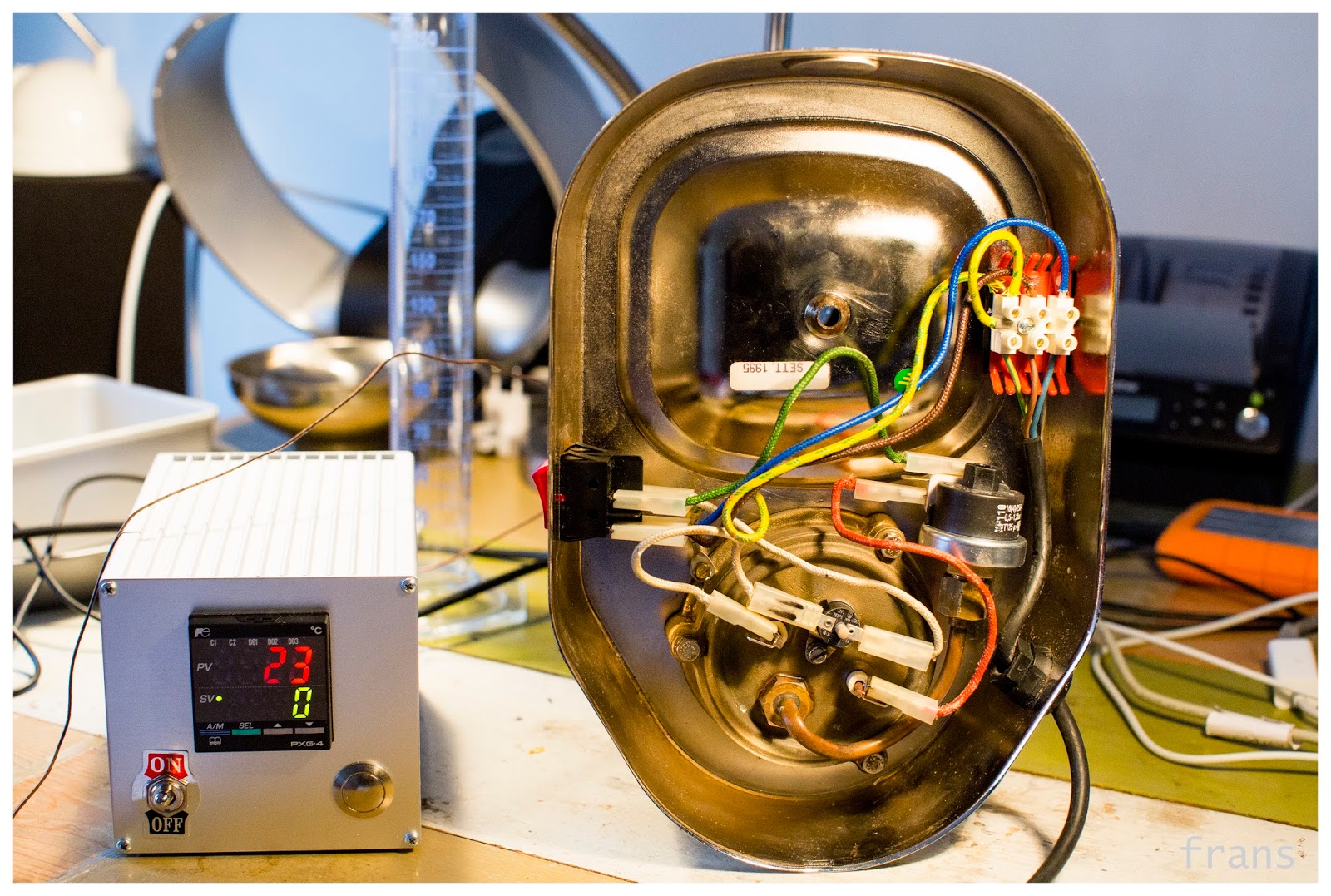

Finished Pavoni & Fuji PXG4 pid: Probe Inside the Ring

Delicious cup: all the work was well invested! At the end of the previous blog about the pressostat and PID working together , I mentioned that I would like to clean up the xmas tree of wires and have as few cables and probes as possible to visually disturb the classic design of the La Pavoni. Getting rid of the probe that was fastened with copper tape to the top of the brew group was a priority. I wanted to hide a new probe in the cooling fin as close as possible to the brew group. This morning I asked Tije if he could do that. He would need to drill a straight hole of 3mm diameter in the 4mm inner ring of the cooling fin that sits as a tight clamp around the brew group. Always the optimist, Tije set to work: First, Tije made a piece of aluminum to fit the inside of the ring. Drilling a thin hole straight through the curved aluminum, if possible tangentially going through the inside of the ring to touch the brew head directly, you need the support of the temporary insid